Current API manufacturing practices are primarily carried out by chemical process and suffers from multiple challenges such as hazardous ambience, safety issues, requires extreme process control, uses multiples of accessory reagents and solvents, yield is less than optimal, many a times non-competitive, uses extensive level of fossil resources to support extreme utility conditions, damages the environment, destructs the climate, and becomes non-sustainable. Until now, effective technology to address the industrial waste is missing.

Burying in the land, which is being done currently, leads to contamination of the soil in and around the disposal site and leaching to surrounding environment. Thus, chemical manufacture is riddled with numerous limitations and addressing them with an enzymatic/fermentative/green technology can lead to the evolution of a competitive manufacturing process while mitigating the environmental impact. It is also increasingly realized that adoption of sustainable technologies is vital for the long-term preservation and health of our environment and economy.

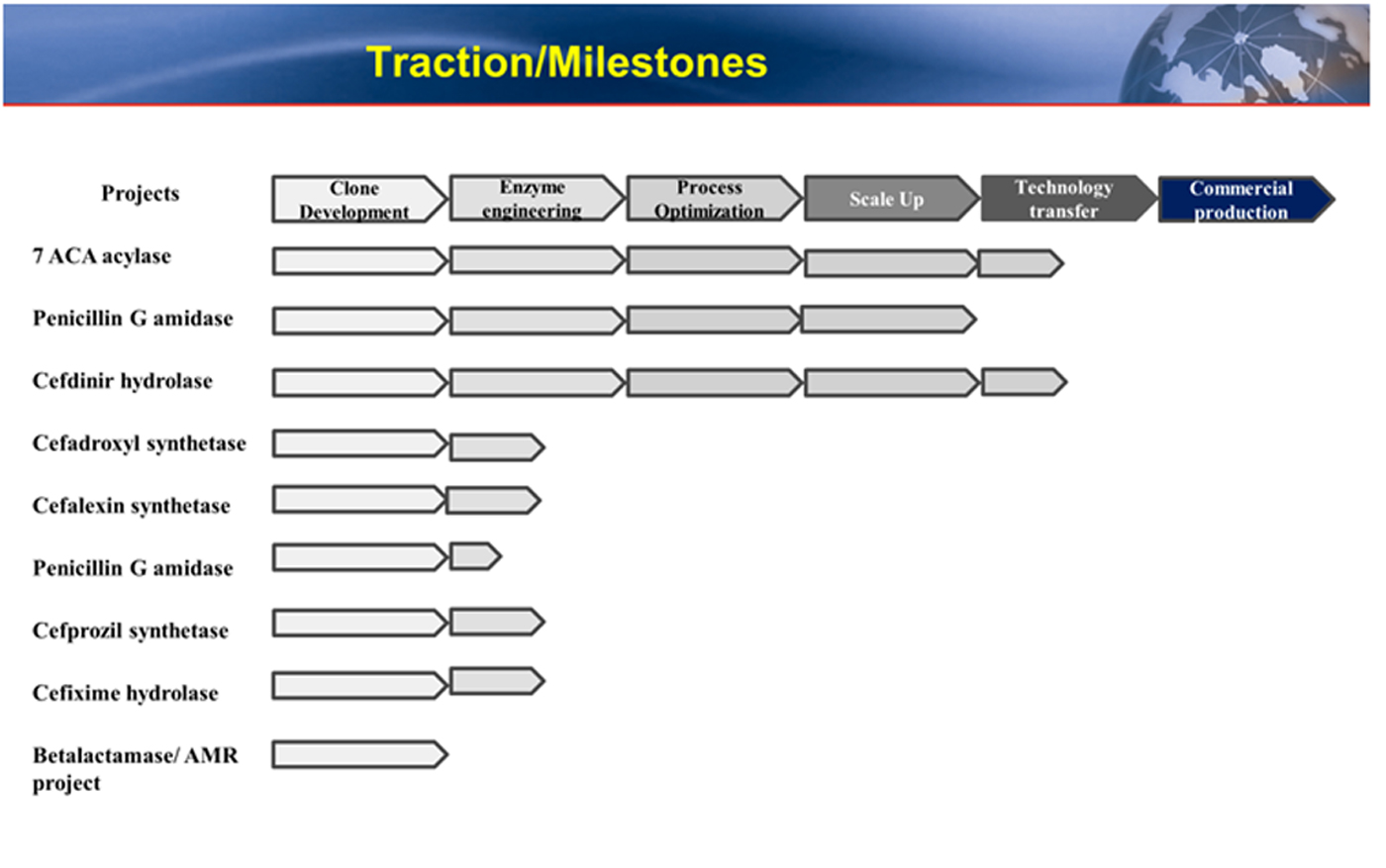

As a reflection of our long-term commitment and passion to preserve our environment and enhance affordable healthcare, we are developing generic as well as proprietary enzyme/fermentative technologies for the manufacture of Active Pharmaceutical Ingredients (APIs). Few of the projects have reached scale up stage while the remaining are under various stages of development as illustrated in the following chart.